Have you ever encountered any of the following annoyances during device debugging or device use?

Complex parameter debugging

Easily debug error

High dependency on debuggers

Cost competition

Equipment homogenization

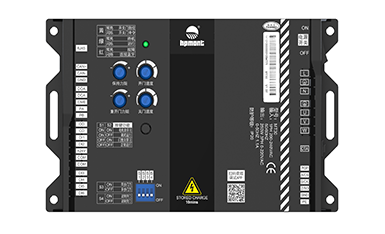

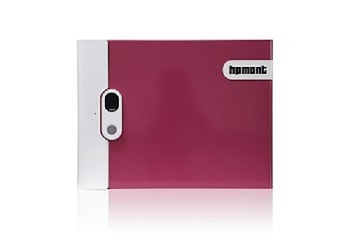

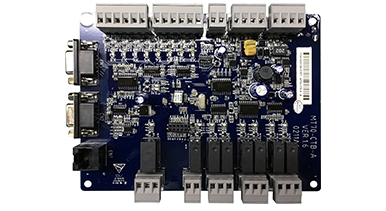

Hpmont has always adhered to technological innovation, continuous output of quality products and solutions to cover more market segments, and with a keen insight into the market, close to the user's needs, to provide users with more professional and appropriate solutions. At the same time, in the product's simple and easy to adjust user experience, technical competitiveness, cost-effective and other dimensions, the Hpmont control integrated machine combination control program, completed the perfect replacement of imported brand inverters and PLC, thus won a good market reputation. In the industrial control field where competition is still dangerous, the replacement of localized technology is crucial.

Program characteristics

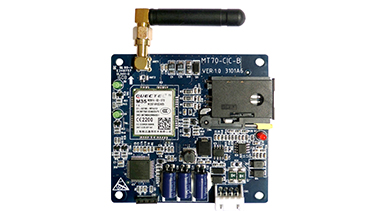

Networking is more flexible

Centralized management, decentralized control mode, and each drive control is an independent programmable control unit.

Communication is more real-time

Support CAN bus

High control precision and fast dynamic response

Simpler operation

Pre-drive, rewind automatically and reducing manual operations.

green technology

Supports common DC bus and reduces power loss.

Taper control for tight winding

Multiple compensation methods

System inertia compensation, friction compensation, material inertia compensation, to achieve stable tension control under various conditions.

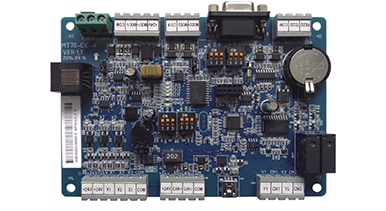

Programming is simpler

The control algorithm is built into the inverter to reduce the difficulty of PLC programming.

Save on electrical costs

Adopting the integrated control to save the PLC in the traditional scheme.

Case sharing

Equipment Information: Gantry Slitting Machine

Application location: Nanjing

Original inverter brand and series: Yaskawa A1000 series

Equipment Information: Solvent Free Machine

Application location: Wenzhou, Zhejiang

Original inverter brand and series: Emerson EV3000 series

Equipment Information: Vacuum Coating Machine

Application location: Shanghai

Original inverter brand and series: Yaskawa V1000 series

Equipment Information: Renovation of double-sided coater

Application location: Guangdong

Original inverter brand and series: Yaskawa V1000 series

Equipment Information: Slitting Machine

Application location: Dongguan

Original inverter brand and series: Yaskawa A1000 series

Equipment Information: Casting Machine

Application location: Dongguan

Original inverter brand and series: Yaskawa A1000 series

For more other industry case sharing, please see the next issue:

Textile