In the last quarter of 2020,

Hpmont special product line supply upgrade,

The performance achieved great growth again, and the production capacity increased to 150% year on year.

These products have been widely used in the industry!

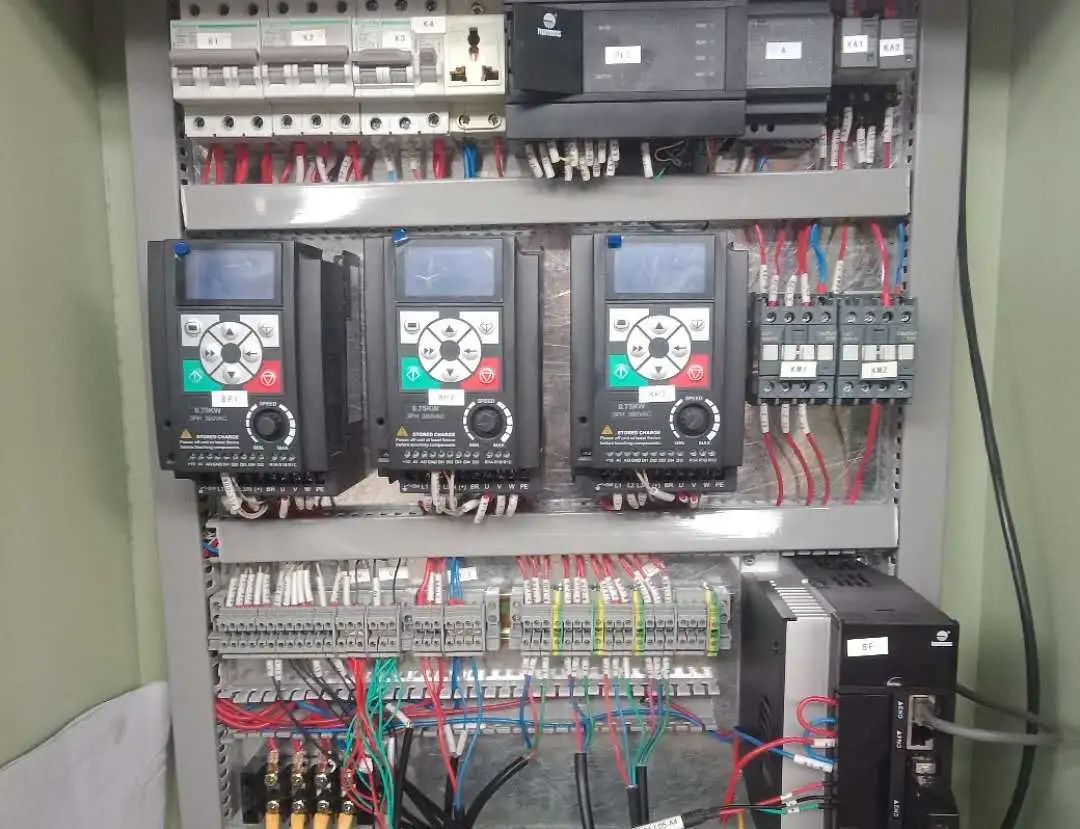

HMI, IPLC, servo and frequency converter are combined to form a product matrix in the field of industrial control.

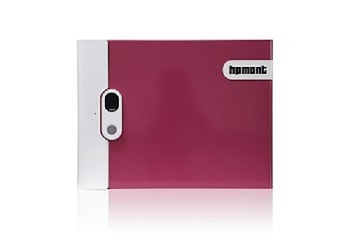

01 HV01 series touch screen

生产于千级洁净度无尘生产车间,采用TFT液晶显示屏,满足工业控制需求,操作界面支持自定义。

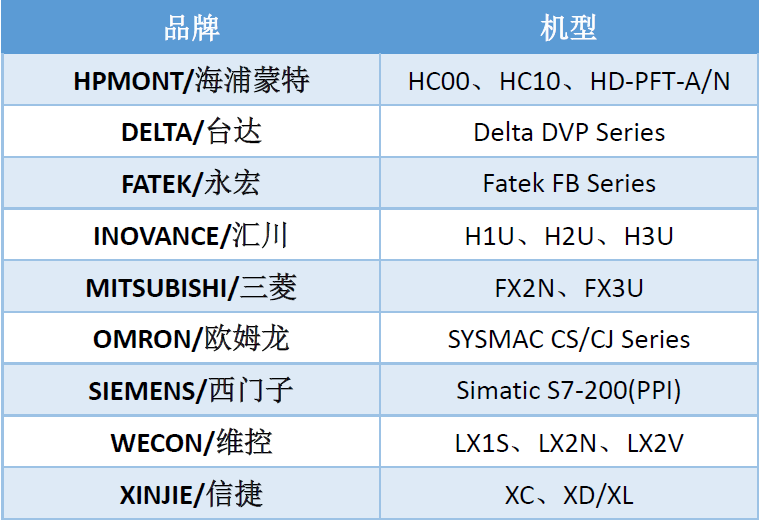

Strong compatibility also enables it to support the major brands of PLC. The supporting brands and models are as follows:

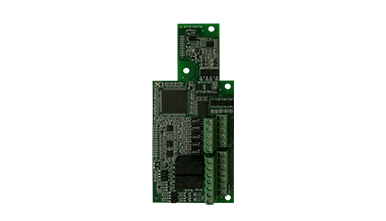

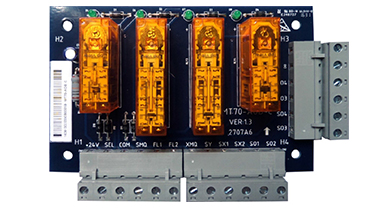

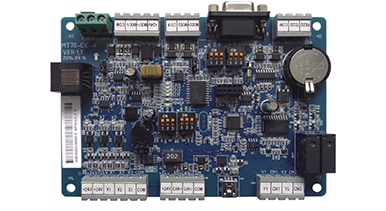

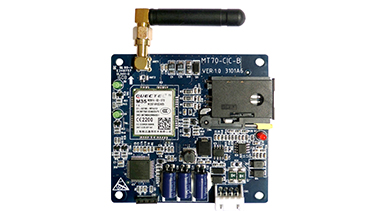

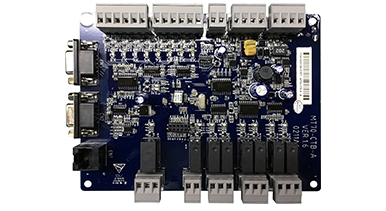

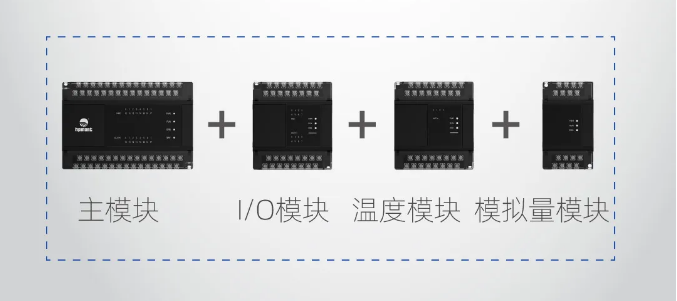

02 HC10 series IPLC

Rich communication interface, encrypt and protect user data, form the best cooperation partner with HMI, and accurately control the whole process.

Multi module configuration, adapt to a variety of complex environments. The maximum number of main module is 64 points, and the maximum number of high-speed pulse input and output is 4.

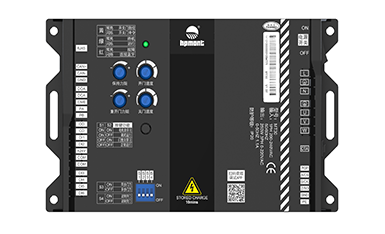

03 HS30 series servo system

HS30 series servo driver small and precise design stands out in many bulky drives, speed loop width of 1.2kHz, encoder feedback accuracy up to 23 bits.

Field application cases

01 dyeing and finishing industry - lining machine

Zhejiang Changxing site, equipped with a full set of solutions: 7 inch HMI, HC0 IPLC, HD09 series and HD3N series inverter. Eight motors control the transmission part, the maximum speed can reach 60m / min, and the running speed is synchronous.

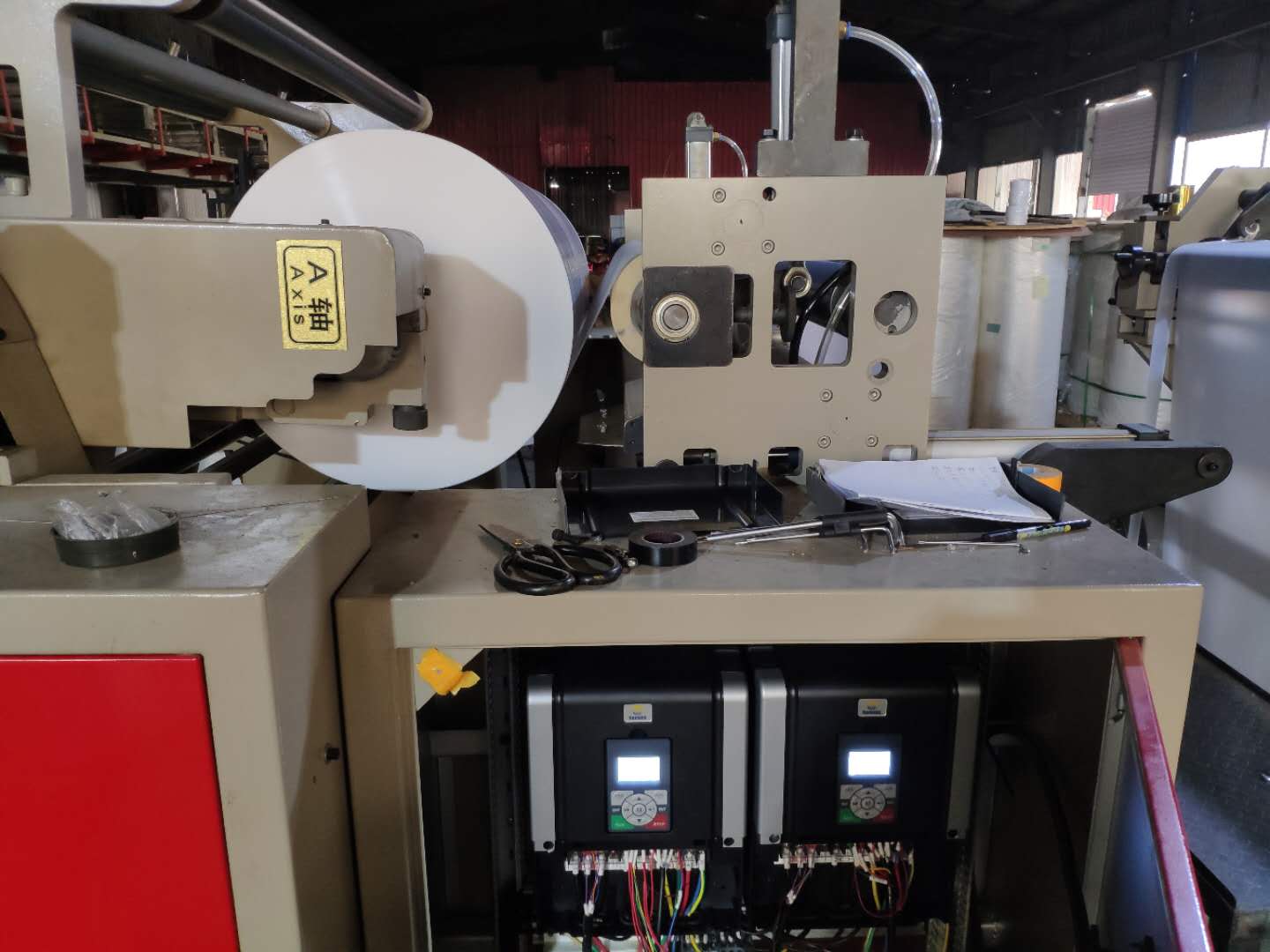

02 cable industry - linear wire drawing machine

Tianjin site, 9-mode linear wire drawing machine, another site equipped with a full set of programs! HV01, HC00, HD30, HD50, HS30 servo, "family barrel" scheme is energy saving and efficient

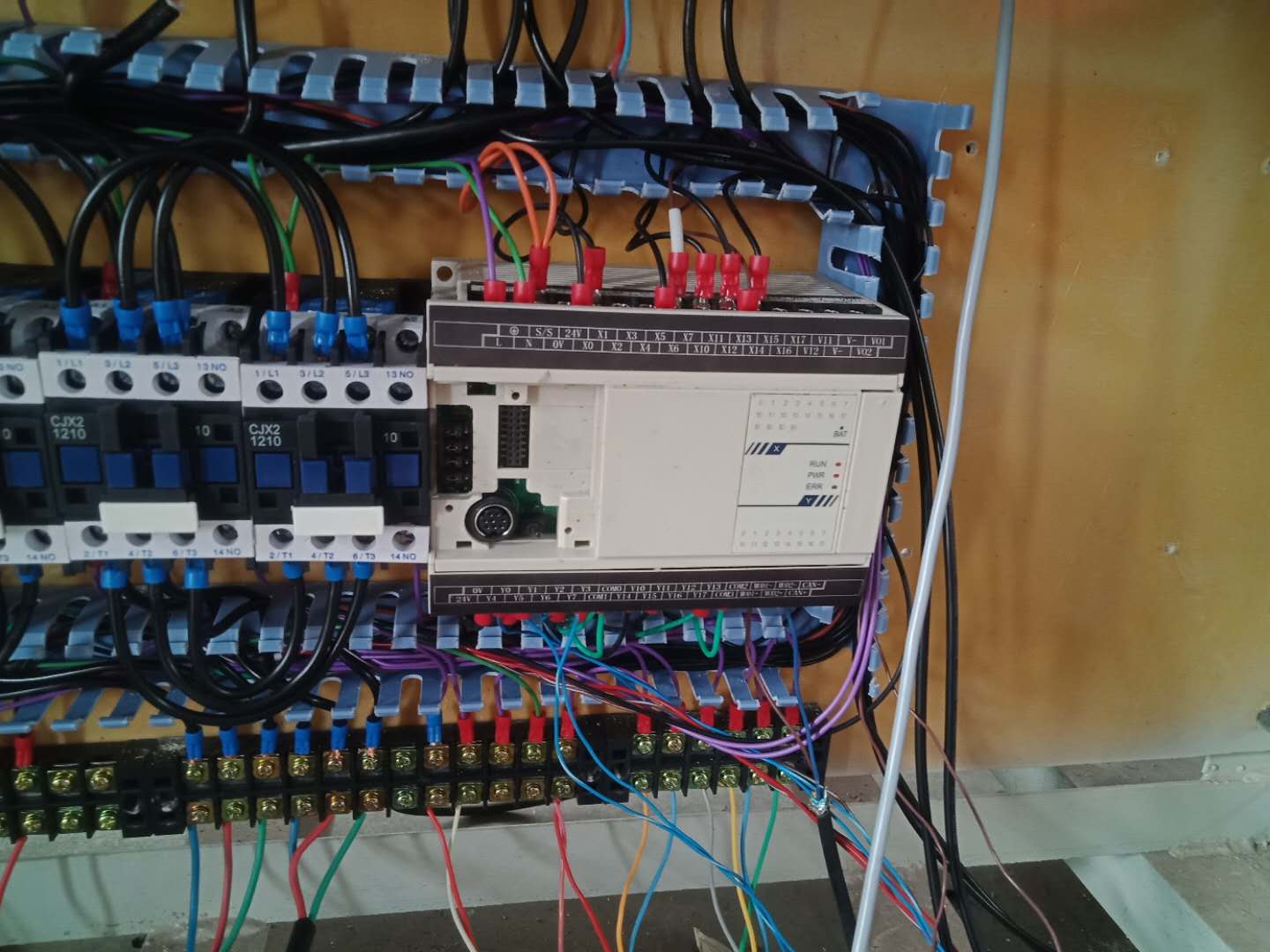

03 cable industry - water tank wire drawing machine

HC10 IPLC and HD30 are used in the equipment factory to control the starting and stopping tension of wire drawing and take-up.

04 cable industry - Extruder

In Dongguan, the extruder is equipped with hc00 iPLC and HD30 inverter.

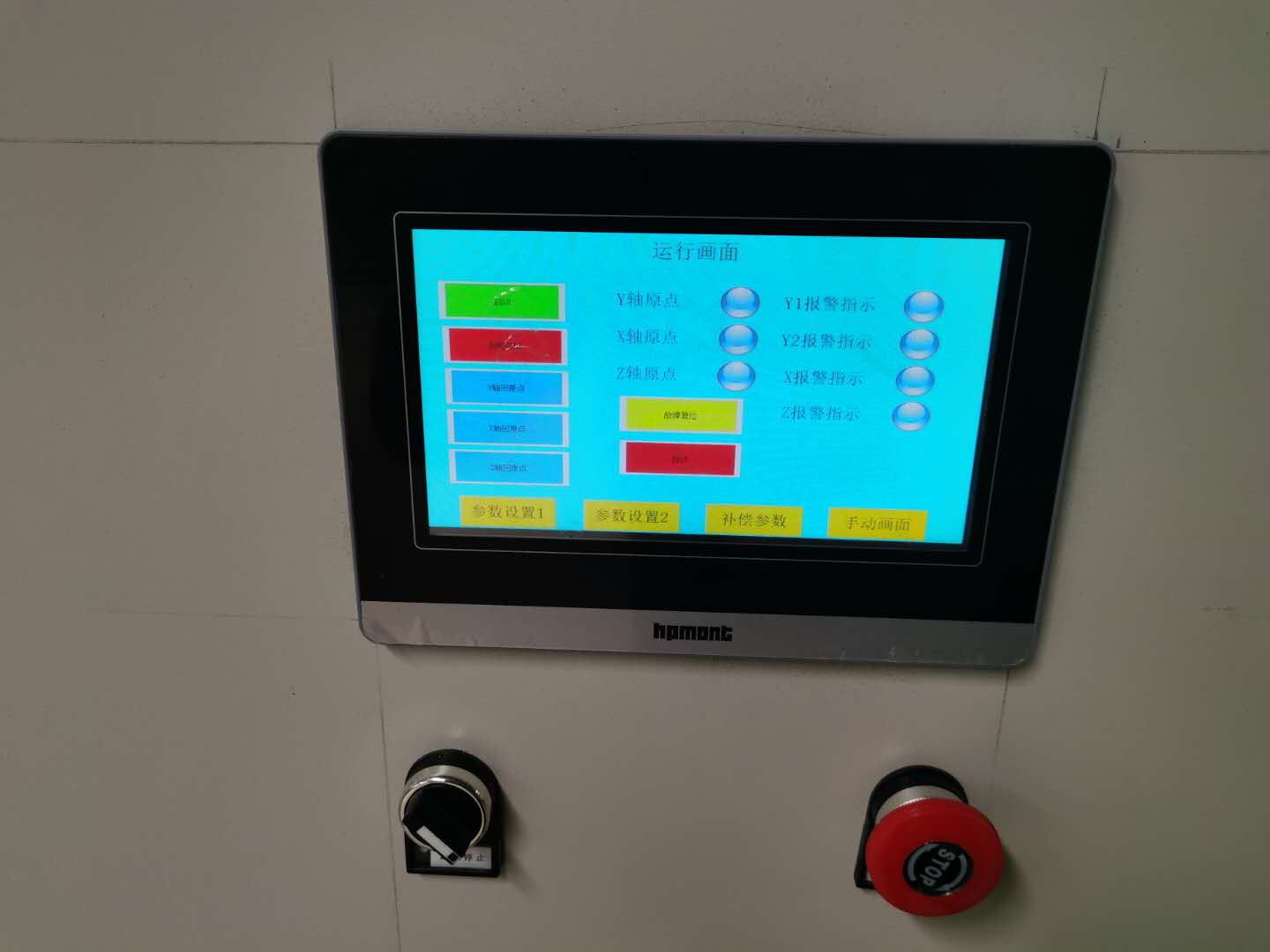

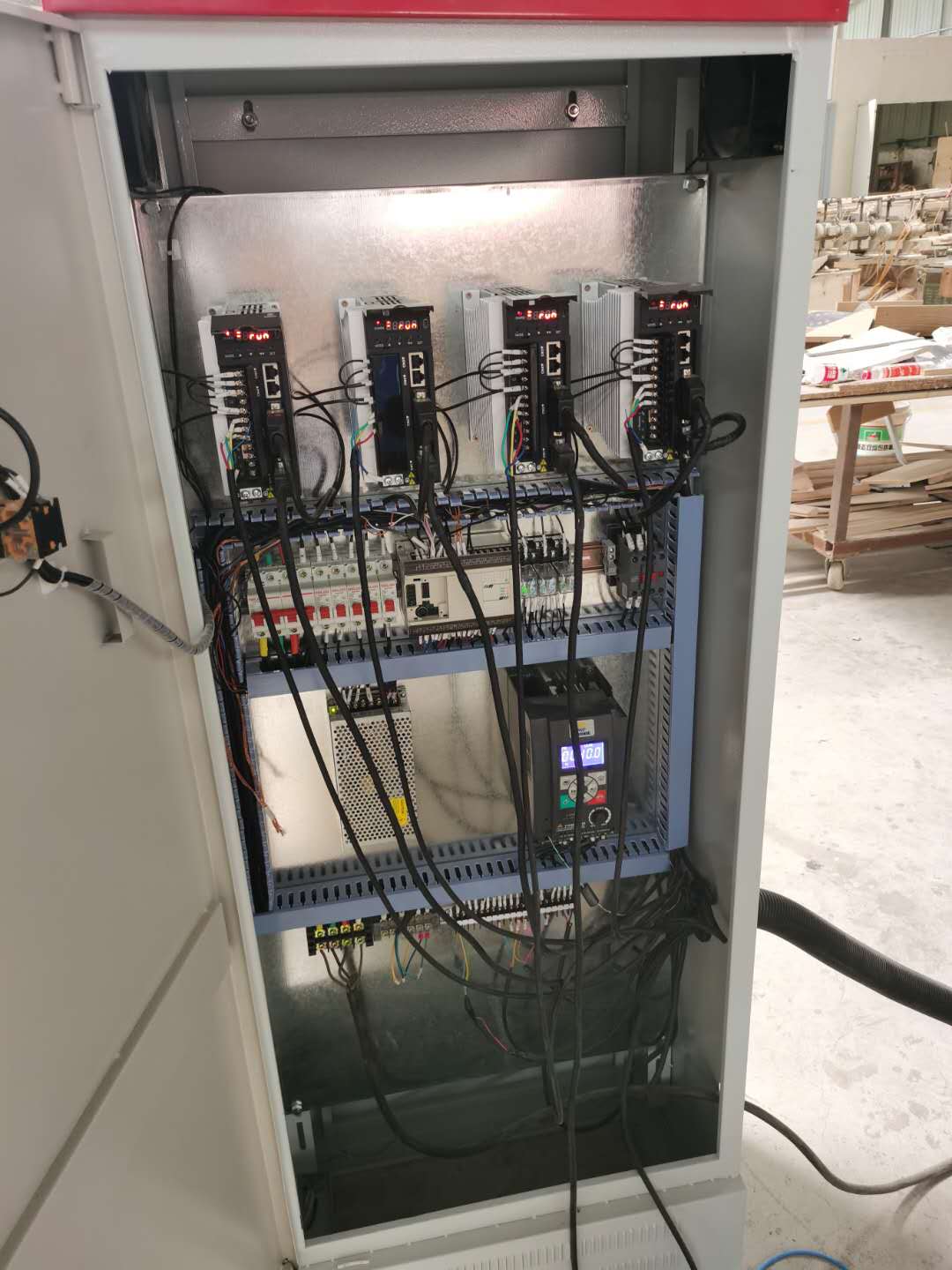

05 woodworking industry - Woodworking puncher

In Jining, Shandong Province, HMI realizes human-computer interaction, HC00 IPLC four axis control, four sets of HS30 servo motors as positioning system, and one HD09 control spindle, which is used for drilling solid wood multi-layer board, and the processing speed is 12m / min.

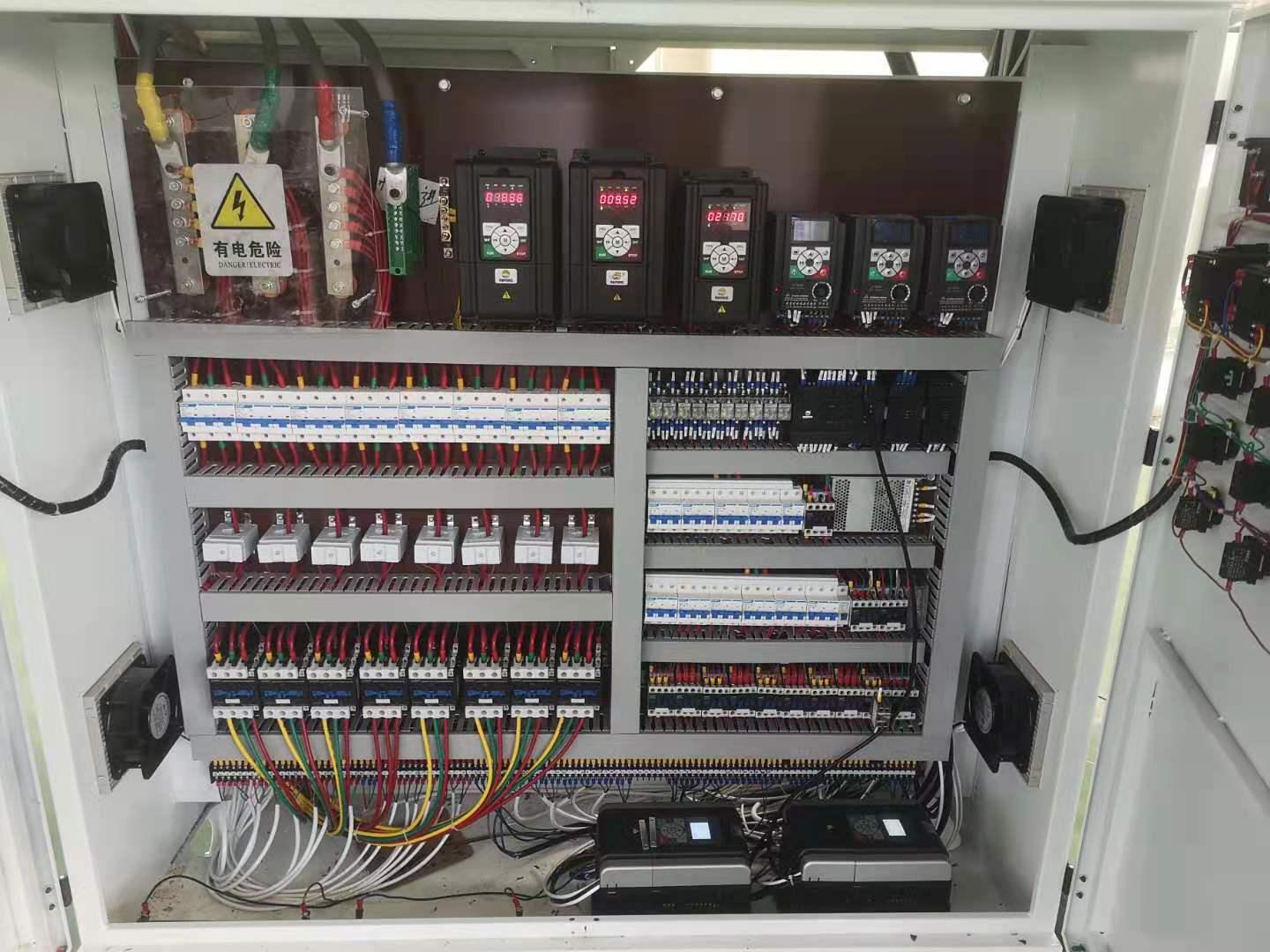

06 package printing industry - coater

Shandong Tai'an site, the application of the latest HC10 IPLC, equipped with hd09, HD20, HD50, constant tension control, double position automatic roll change.

07 package printing industry - coating machine

HC10 IPLC with HD50 series inverter, double position automatic coil changing.

08 plastic industry - film blowing machine

In Shandong field, HV01 touch screen, HD30 and HD20 frequency converter are used for film blowing machine. HV01 displays the running status of the equipment in real time, HD20 controls the logic and weight of the meter to heat the plastic particles and blow them into film.

09 paper tube machine

In Baoding, Hebei Province, HC00 IPLC and HS30 servo axes control the cutter to move back and forth, keeping the linear speed between 20 and 30 m / min.

More industry complex scene, muscle paste rewinder, strander, carbon fiber winding machine, coater, rock wool packaging machine

On the road from a single product to a full range of solutions, hipmont has been steadily following the concept of value creation.