Hpmont has been focusing on the research of industrial control systems and now has complete system solutions.

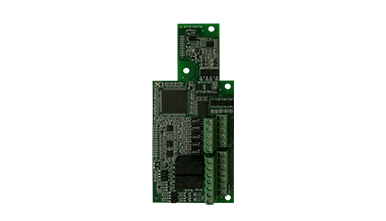

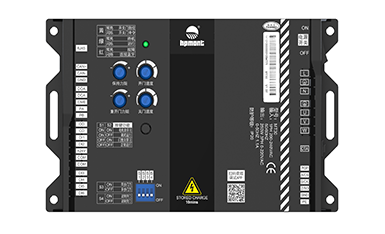

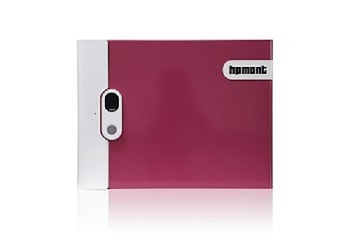

After a series of continuous improvement and field practice, the newly upgraded HC10 series IPLC comes out with powerful functions. It integrates data acquisition, logic control and motion control with powerful performance. At present, it has been widely used in cable, lifting, printing package, dyeing and finishing industries.

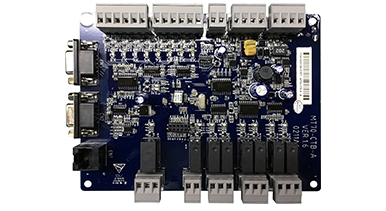

The HC10 Series IPLC main module supports a maximum point of 64 points, and extensions to 192 points can be added continuously.Input and output support 4 high-speed pulse signals of 100KHz respectively.Provides 1GHz high-speed computing capability to process data information at high speed.

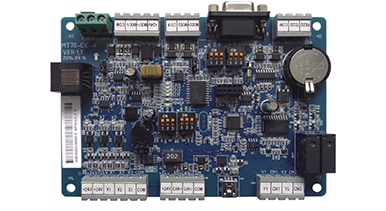

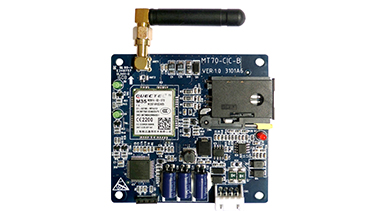

One CAN bus, two RS485, one 422...

A variety of communication methods, and hardware interfaces to match each other, more powerful compatibility.

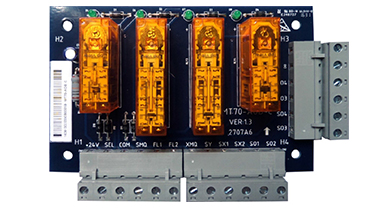

Multiple Extension Modules: Temperature Module, I/O Module, Analog Module...

Maximum expandable 8, high flexibility, strong collocation, to meet the needs of different equipment environments.

In order to protect users'data and intellectual property rights, users' data and special addresses exist in flash, even if the power is off, they are not afraid of data loss!

HC10 was recently installed on the assembly line at the Hpmont Intelligent Factory, which has been in service for 10 years. So far, all the production equipment of Heipumont Intelligent Factory has completely realized the replacement of its own brand, and truly realized the manufacture by itself of the Intelligent Factory.

Nowadays, in the pipeline, HC10 series IPLC is planning the whole process. The stable and excellent performance can promote the automation, efficiency and accuracy of the production and manufacturing process.

The entire production line workbench is logically controlled and the smooth operation of the conveyor belt is controlled orderly.Real-time monitoring of the conveyor station to ensure that the material transfer interval is accurate, 0 error, natural 0 delayed work, improve the production efficiency of the entire intelligent plant.