I heard that the construction industry of high-rise buildings is most afraid to encounter the following situations:

Wind, frost, rain and snow delay

Rental of equipment "never return"

Accidental personal and property damage caused by ups and downs...

However

For MTCC-Y3 Elevator Control Cabinet + Well Construction Lift

These are small cases without care.

External hanging/well way type

1. Operating environment changes from open air to indoor, and the probability of missed work in weather is 0;

2. Closed well way to effectively isolate dust, noise, light pollution, etc., to meet the requirements of civil construction;

3. No need to lay foundation, bury steel parts, fill inlet and other primary and secondary construction, save a lot of manpower and material resources.

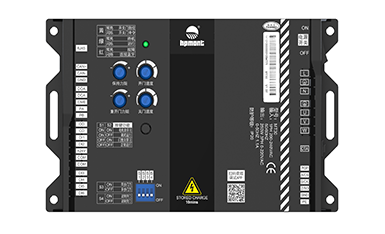

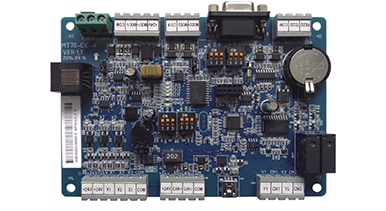

In accordance with the operation characteristics of construction lifts and their special safety requirements, Hpmont has put forward the solution of well construction lifts control system.

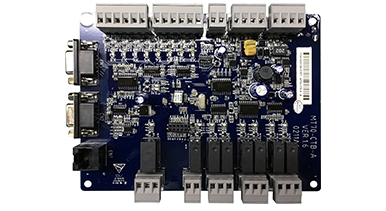

The integrated MONT70 controller is built into the MTCC-Y3 control cabinet, which uses frequency conversion drive and closed-loop control of encoder. At the same time, it supports remote monitoring of equipment, improves operation efficiency and reduces energy consumption. The equipment is more secure and controllable in use.

1. Construct by High-Speed Rail to reach the whole floor easily.

Stepped speed up to 4m/s, 8 times higher than traditional exterior-mounted construction lifts, full floor (including basement) construction with the assistance of high-speed rail.

2. Variable frequency drive, low power consumption and high energy efficiency

Traction variable frequency drive reduces operating energy consumption greatly and combines high efficiency and energy saving with low power of main engine and high power transmission efficiency.

3. Precise flat layer with safety factor up to 13.5

Encoder closed-loop control, high level accuracy; No tipping torque, avoiding accidents caused by breaking standard knuckles, safety.

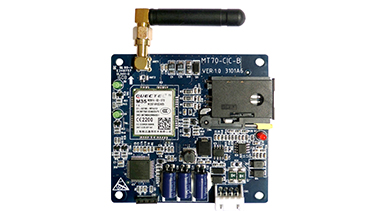

4. Support GPRS remote monitoring and equipment traceability

In order to solve the problem of "never return" for elevator equipment leasing, the Hpmont MTCC-Y3 control cabinet supports remote tracking expansion module, which can monitor and manage the operation status of field equipment in real time by using supporting software.

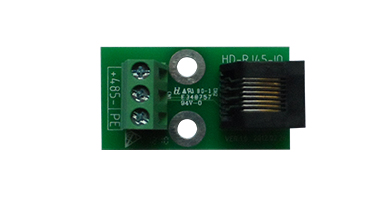

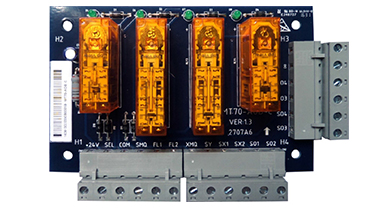

5. Interface board design reduces wiring arrangement and facilitates installation

Fewer wiring, plus parameter "one-button-through" debugging-free, easy and fast installation, conducive to later maintenance operation.

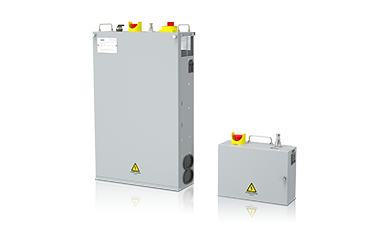

Full Scheme Application - MTCC-Y3 Control Cabinet

Application Site of MTCC-Y3 Control Cabinet in Foshan, Guangdong

Anhui, MTCC-Y3 control cabinet and application field of related ancillary products

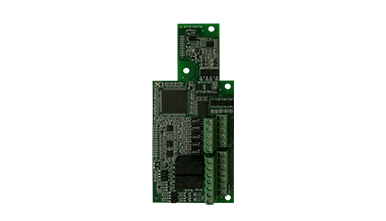

Individual application - MONT70 integrated controller

Henan, 150+ MONT70 and its supporting products, 1.5m/s step speed, 1600kg load

MONT70 application field, Hebei, with step speed of 0.5m/s and load of 1000 kg