The coating machine is used for coating production of paper, cloth, leather, aluminum foil, plastic film, etc. This machine applies a layer of glue, paint or ink that has a specific function to a roll of the substrate, and then winds up after being dried. It adopts a special high-speed coating head, which can effectively reduce the generation of air bubbles. The rewinding and unwinding of the coating machine is equipped with a full-speed automatic film-connecting mechanism and a tension closed-loop automatic control.

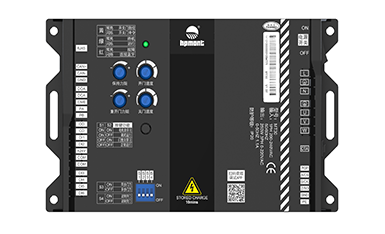

The core control part of the high-speed coating machine produced by a company in Haining was selected from Hpmont inverter.

The coater applies a layer of silicone oil to the roll of sanitary napkin paper. To prevent the penetration of the silicone oil, a layer of glue is applied before the silicone oil is applied. After applying the glue and silicone oil, it is necessary to immediately dry it at the appropriate temperature.

Gluing requires low synchronous speed and passive coating, eliminating the need for a frequency converter to control the synchronous speed. When silicone oil is applied, it requires high synchronous speed and active coating, and the inverter must be installed to control the synchronous speed of the drum and the rewinding drum.

Specific features:

The linear velocity is up to 240m/min, good system synchronization and stability;

Stable system tension, and the tension fluctuation during the lifting speed process is small;

Low allowable tension of paper, and higher response of the system is required;

The coated silicone roller must be synchronized with the rewinding roll to ensure uniform coating;

The temperature requirement of the drying equipment is strict. If the temperature is too high, the paper will be burnt. If the temperature is too low, it will not dry in time, resulting in material breakage.

The winding forming effect is good, and the waste of raw materials is avoided to the greatest extent.

Application requirements for inverter

Winding part:

Constant tension control, maintaining a constant tension throughout the winding process;

Fast torque response to avoid large fluctuations during acceleration and deceleration;

High-precision speed control, dynamically adjust the inverter output frequency in real time, keep the tension constant throughout the unwinding process;

Good winding and forming effect;

Unwinding part:

Constant tension control, maintaining a constant tension throughout the unwinding process;

Fast torque response to avoid large fluctuations during acceleration and deceleration;

High-precision speed control, dynamically adjust the inverter output frequency in real time, keep the tension constant throughout the unwinding process;

With two-way unwinding and reverse tightening;

Maintaining constant torque during power generation state;

Application

The maximum linear velocity of the system reaches 240m/min. When in the steady state, the tension fluctuation does not exceed 1kg, and the speed cannot exceed 5kg during the lifting speed. The requirements of dynamic response of the inverter speed and torque of each link is extremely strict.

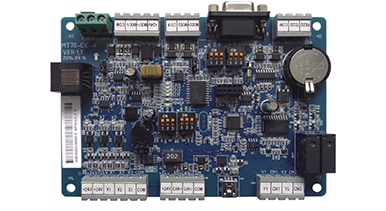

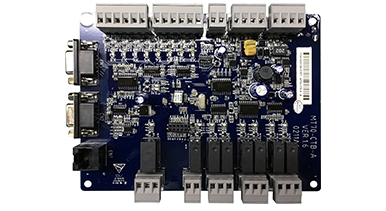

The field equipment is driven by the inverter including five parts: main machine, winding, unwinding, traction, and silicone oil roller. In order to meet the requirements of high synchronism and high precision control, all inverters adopt vector control mode with PG.

Winding: 1 7.5kW HD50 driver adopts speed control torque limitation mode, one channel 0-10V analog quantity is given as frequency reference, one way 0-10V analog quantity as the torque limit, realizing empty roll 100mm to full roll 1000mm winding. High-precision speed control of HD50 drive ensures constant linear velocity and fast torque response characteristics ensure constant tension;

Unwinding: 1 11kW HD50 driver adopts speed control torque limitation mode, one channel -10-10V analog quantity is given as frequency, which can realize bidirectional unwinding and reverse tightening function, one way 0-10V analog quantity as the torque limit to realize the full roll 1000mm to the empty roll 100mm unwinding. High-precision speed control of HD50 driver ensures constant linear velocity and fast torque response characteristics ensure constant tension;

Main unit: 1 3.7kW HD50 driver, one channel 0-10V analog quantity is given as the frequency reference, high precision speed control of HD50 driver ensures constant linear velocity;

Silicone-coated roller: To maintain the synchronous speed, a 3.7kW HD50 driver is used to drive the roller. The analog quantity of 0-10V is used as the frequency reference. The high-precision speed control of the HD50 driver ensures the linear velocity is constant.

Traction: A 3.7kW HD50 driver, one channel 0-10V analog is given as the frequency reference. High-precision speed control of HD50 driver ensures a constant linear velocity.

Summary

After the commissioning is completed, the high-speed speed control and fast torque dynamic response characteristics of the Hpmont inverter achieve stable operation of constant tension and linear velocity throughout the whole process. And the products of Hpmont have been unanimously recognized by equipment manufacturers and customers.

Up to now, the equipment has been running stably for several months, and the zero failure rate has greatly improved the production efficiency of customers.